About Philips Variable Building System

Historical background

The Production Mechanization (PM), an instrument to fullfill in a companies need of specific production capabilities within an industrial setting, focussed on mass fabrication is as old as the company itself.

Until WWII consumer products were manufactured mainly by hand. After WWII, living standards of an ever growing population did rise rapidly, which resulted in an increasing demand for consumer goods. Manual production within an industrial setting was no longer profitable.

Instead of manually manufactured goods, machines took over the work. These machines had to be desigend first and the designing process itself is an intriguing process.

The development of prototype machines was partly done behind the drawingboard and partly by real prototyping with custommade parts. The materials used were often produced conform high engineering standards. This method of designing however was expensive and timeconsuming.

One of the ways to simplify this process was to use ready built parts to be used within a modulair system.

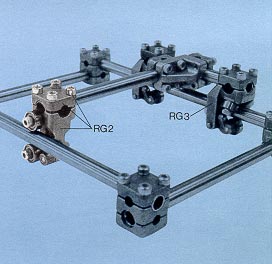

The purpose is to design and construct mechanisms and machines. If one has constructed and tested such a mechanism it either can work or not. If not, the mechanism must be modified until it meets it’s requirements. This proces can be done rapidly with a modulair system only.

Development of the Variable Building System

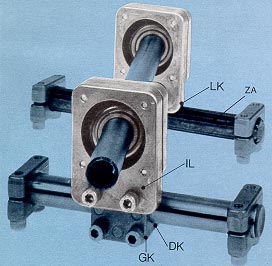

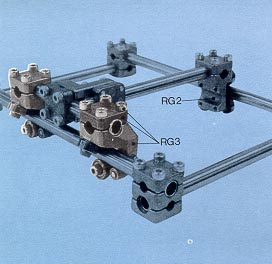

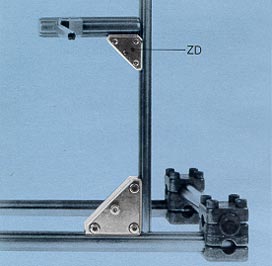

Philips introduced in 1970 within retrospect to the historical background a modular system to the market. Ir Arie Kraan invented the VBS and it was commercialised by the Nederlandse Machinefabriek Alkmaar (until the early 1990’s owned by Philips) with the following characteristics:

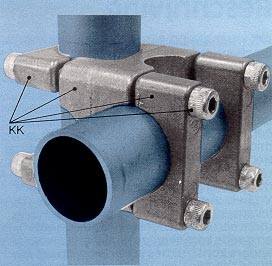

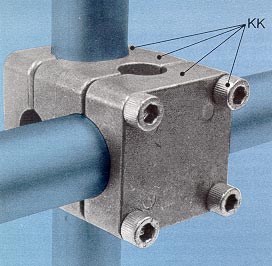

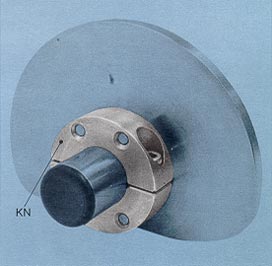

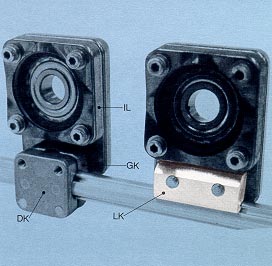

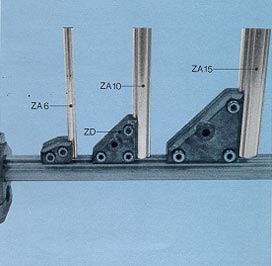

- the range is intentionally limited to a few (internationally) preferred diameters: 6 - 10 - 15 - 25 - 40 en 60mm

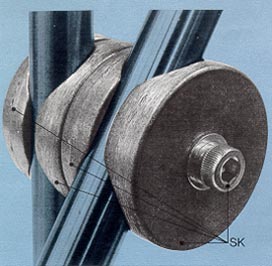

- no fixed pitch, all components are infinitely adjustable

- all clamp elements are seperable

- designs can be made rigid and free from backlash

- suitable for both static and dynamic applications

- can be used in conjunction with all other equipment building systems, standard products and existing structures

- re-usable

- can be put together rapidly and it is easy to make changes or modifications any later date

The diameter range was initially limited to 15 en 25mm and the system was called Building System, but by 1976 it had been developed into a full grown system and was renamed into Philips Variable Building System.

It’s interesting to mention that there are definitely some similarities between the FAC system and the VBS. One important similarity is that both systems make infinitely adjustable clamping possible. VBS uses larges diameters and therefore the dimensions of a prototype is not limited to the tablescale.

In spite of these similarities, the VBS was an autonomic development, based on marketdemands of that time. The development was initiated by a small group of Philips engineers whose responsibility mainly was the mechanisation of the company. The VBS had at first place been developed for internal use, but became soon available to the market.

In the early 2000(?) the Variable Building System got a new owner: Spanpartner. As far as I know the VBS was for sale until approx 2015, before other similar systems took over the market.

Sources:

- Interview with ir. A. Kraan dd 15 april 2008

- About the Variable Building System, ir. A. Kraan dd 5 mei 2008

- Vakantieleergang werktuig- en scheepsbouw 1964 - prof. ir. W. van der Hoek

- VBS catalog 1980