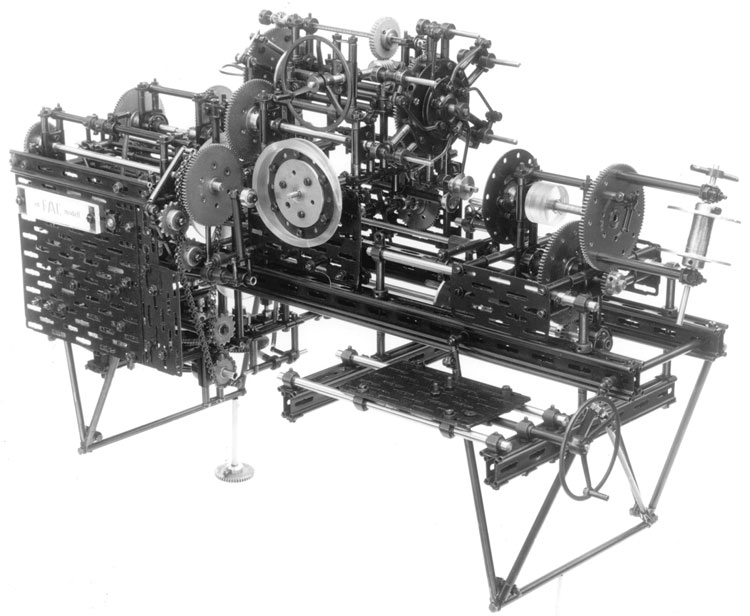

Machine for testing sintered materials

(Photo with courtesy of Fac system)

(Photo with courtesy of Fac system)

(Photo with courtesy of technisch bureau Koppe)

(Photo with courtesy of technisch bureau Koppe)

(Photo with courtesy of technisch bureau Koppe)

(Photo with courtesy of technisch bureau Koppe)

Machine for testing sintered materials. One of the most elaborate models ever made in FAC.

The model has been designed and built at the Swedish Institute for Metals Research, most likely in the early 1960’s. Although the office of Koppe has a large photoformat of this machine, it is not likely, that the owner of the Koppe office, Mr Koppe Sr was involved in developing this machine.

The machine was used to test sintered materials by spooling thin metal wires in a strictly parallel fassion (not generaly the case by standard winding machines). It’s interesting to mention, that Philips developed the technology for orthocyclic coilwinding, a type of winding which seems to be related with the functionality of the above pictured machine.

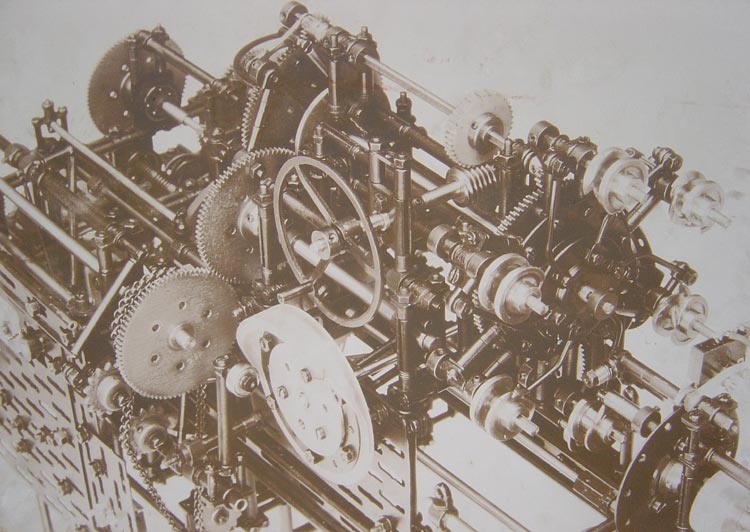

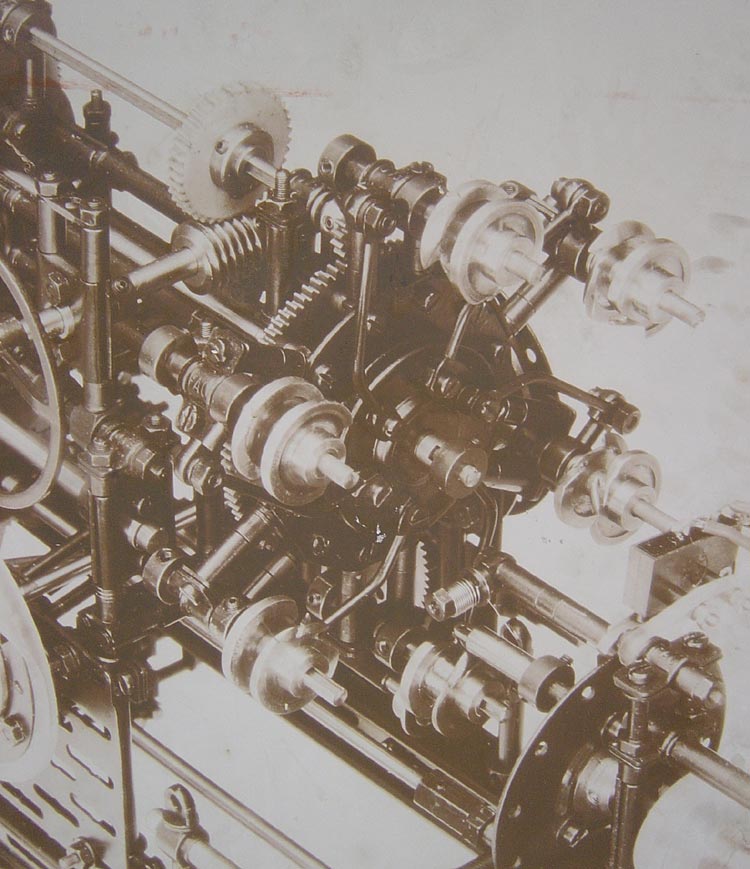

De gearbox is very compact, the camwheel is custommade, but it’s application is not unusual in FAC. The spindle seems to incorporate 2 functions: by rotating the spindle a coil (to be placed on the centre axle of the spindle) is getting winded. The camwheel provides a certain translation, possibly axial to the spindle, but this is just an assumption, due to the lack of more info. The custommade pulleys and the special shape of the flange suggest a precise positioning of the wire relative to the coil.

Please contact the author of this article if you can give more info about this machine.